WORKS

NOMURA MEDIAS meets TOHOKU NITTO KOHKI

We struggle and take on challenges together—

Built as one team, a showroom

linking history and the future

Space Promotion

2025.07~

On July 1, 2025, a new manufacturing hub opened in Ozaso, Fukushima City.

The "Ozaso Factory," a flagship symbol of the company's new start after MEDOTECH Co., Ltd. (Yamagata City, Yamagata Prefecture) and SHIRAKAWA NITTO KOHKI Co., Ltd. (Shirakawa City, Fukushima Prefecture) merged in 2024 to begin operating as TOHOKU NITTO KOHKI Co., Ltd. MEDOTECH produced machine tools and annular cutters, while SHIRAKAWA NITTO KOHKI manufactured door closers and electric screwdrivers. By combining the technical capabilities and production know-how each company has cultivated, the newly consolidated plant has become a standout presence in the verdant landscape of Ozaso.

"We are right by the Ozaso Interchange and next to a roadside station, a location that naturally catches people's attention. It also increases the chances that they will take an interest in the factory. If that is the case, we wanted to make it a 'factory worth seeing' not only from the outside, but on the inside as well," says Plant Manager Tetsuya Kuwabara. "Because our products are primarily for business customers, many members of the public do not really know what kind of company we are. We decided to create interior exhibits and a tour route so more people can learn about our history, what we make, and the people who work here."

NOMURA MEDIAS was selected to lead the design and layout. "Their proposal was excellent, and the exhibitions they delivered for other companies were also impressive, so we knew we wanted to ask them," Kuwabara continued. The project began with a clear request: create a showroom that expresses who TOHOKU NITTO KOHKI is, with an uncompromising focus on clarity and understanding.

NOMURA MEDIAS proposed a three-part experience, "Learn," "Touch," and "See," designed to let visitors feel the company's appeal firsthand.

Visitors begin in the "Learn" zone, where exhibits trace the story from the founding of the predecessor companies to the creation of the Ozaso Plant, alongside representative products. Next, in the "Touch" zone, they handle the real products and experience what makes them compelling. Finally, in the "See" zone, with that knowledge and hands-on experience as context, they tour the manufacturing floor where employees are at work. Many of the products are unfamiliar to the general public, but by weaving this sequence into the showroom, it becomes a story-driven experience anyone can enjoy while deepening their understanding, regardless of role or generation.

The Ozaso Plant, born from

the integration of two companies' capabilities, reimagined

as a place to share the company's story and appeal

A “showcase factory” designed in harmony with its rich natural surroundings. Its defining façade was created by Kengo Kuma.

Workshops where employees spoke candidly

and strengthened their bonds

The overall direction for the showroom was set, but to elevate the exhibition content, the team needed to gather opinions and requests from a wide range of employees.

Natsumi Nishikiori, who led the planning, reflects: "The hardest part was the very first step, organizing TOHOKU NITTO KOHKI's strengths and appeal, then putting them into clear words. Many employees were participating in exhibition-making for the first time, and the two former companies also had slightly different ways of thinking, so it took a great deal of time to shape the content into something everyone could agree on."

To break through this challenge, NOMURA MEDIAS proposed a workshop program.

"It was an idea designed to capture employees' real voices," says Nishikiori. "We brought together people from the Yamagata and Shirakawa plants, and through the workshops, we wanted to explore where TOHOKU NITTO KOHKI's strengths and appeal truly lie, and what defines the essence of TOHOKU NITTO KOHKI.

In the workshop, which brought together mainly younger employees from the manufacturing floor, the team began by digging deeper into the results of a pre-workshop survey through discussion. It became clear that mid-career employees, especially those living with their families, felt excitement about the new plant, while also carrying anxiety about working in a new environment. And when asked, "Who would you like to visit the new plant?" many survey responses focused on the company's future, such as "people who could become future recruits." But as the discussion went on, a more candid wish surfaced: "But honestly, we want our families and friends to come see it, too!"

As the conversation deepened, the group also aligned on a key point: simply lining up products does not communicate their value, and precisely because these are products people rarely encounter in everyday life, careful explanation is essential. What stayed with Nishikiori and the team was each employee's passion for manufacturing, and the strong trust they placed in the colleagues they work alongside.

Group work was also conducted to revisit the appeal and key selling points of the company's flagship products.

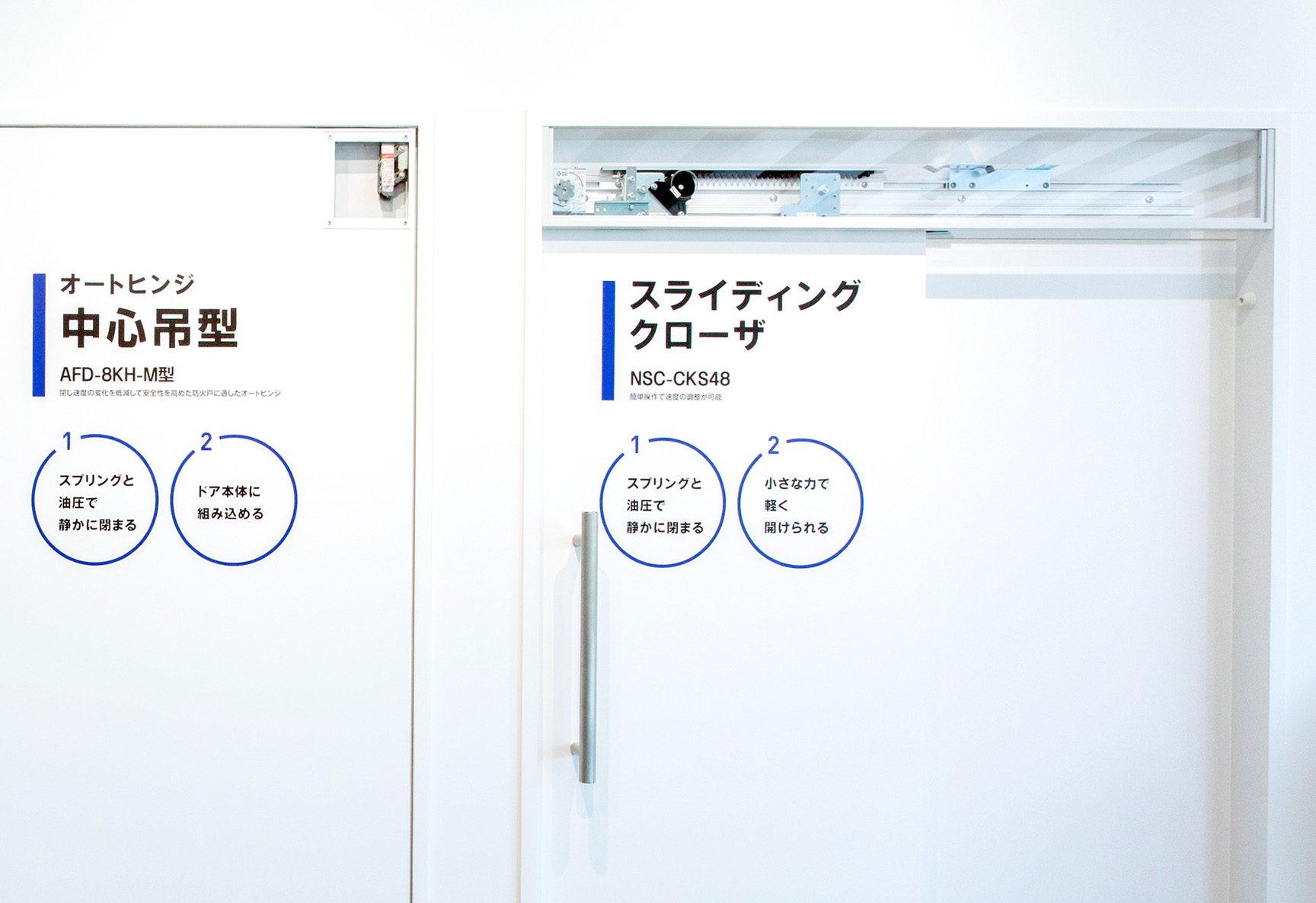

The team that discussed the door closer, a device that automatically closes a door slowly, shared how TOHOKU NITTO KOHKI door closers are used in familiar places like Shinkansen restrooms and phone booths, as well as in safety-critical applications such as emergency tunnel phones and fire doors. They highlighted the product's strengths, including its wide range of variations and the ability to accommodate custom orders.

Through the workshop, employees exchanged frank opinions and reaffirmed together what defines TOHOKU NITTO KOHKI. Designer Minami Ohashi reflects, "Being able to hear employees who actually make the products speak directly about their pride and feelings toward their work made it an incredibly meaningful time."

Kuwabara also notes that the workshop was more than a simple exchange of opinions. "Young employees on the manufacturing floor rarely have the chance to explain the selling points of their work to others. And because they worked at separate plants, they had almost no opportunities to meet, so they could not really see each other's work. I think this workshop became a very valuable opportunity for people to get to know one another."

Some of the employees who joined the workshop went on to participate in the project as core members. Kuwabara continues, "Employees began communicating with each other and developed a real sense of unity, with the feeling of 'We are going to the new plant!' Moving from Yamagata or Shirakawa to Fukushima takes effort, and I think some people felt uneasy about it. But through the workshop, an awareness emerged that they wanted to share the appeal of their work with many more people, and that may have been a great catalyst for shifting into a more positive mindset."

In designing each zone, NOMURA MEDIAS and on-site employees met again and again, building the showroom through steady trial and refinement with "clarity" in mind.

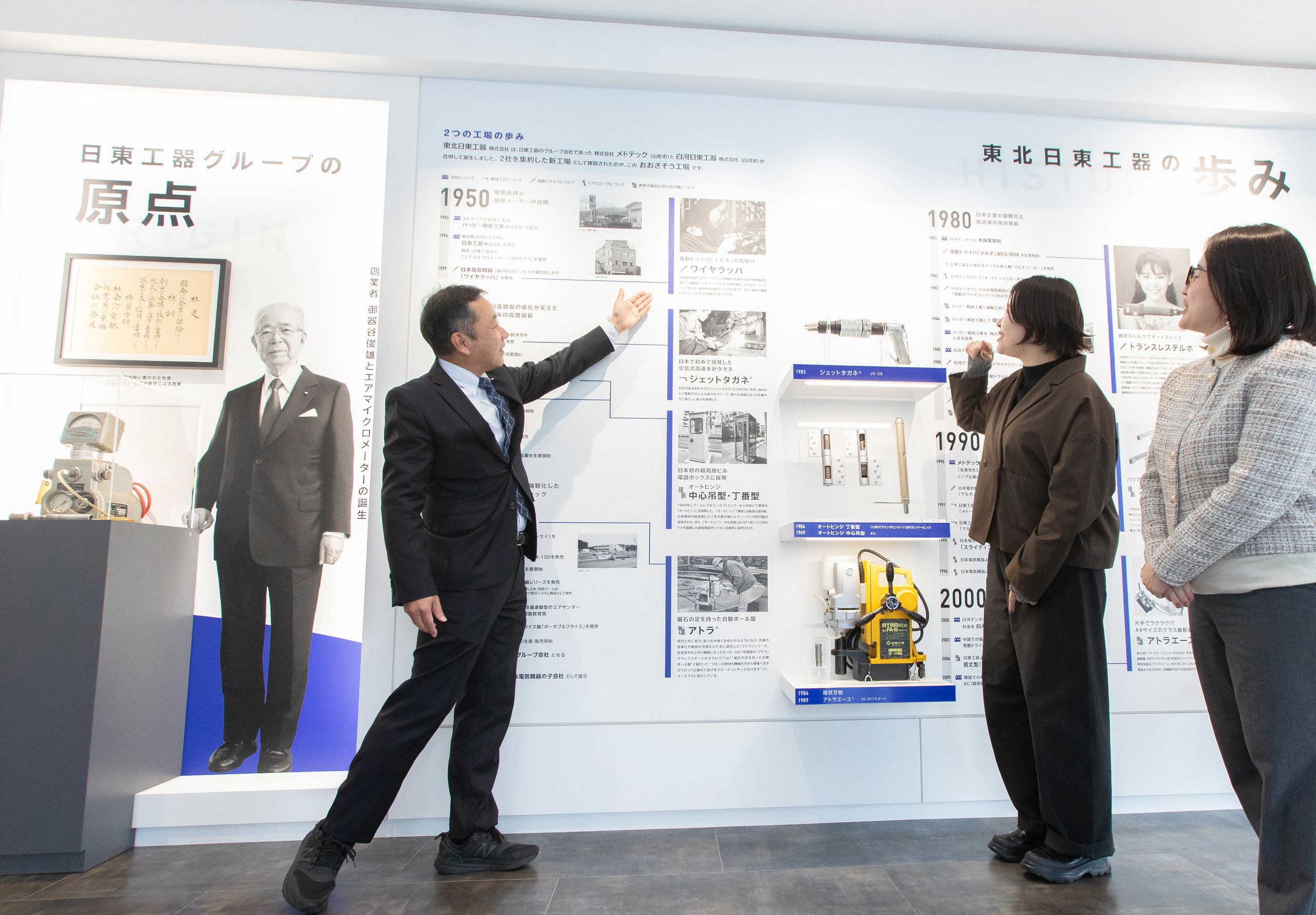

In the "Learn" zone, a timeline titled "The Path of TOHOKU NITTO KOHKI" traces how two companies with different roots, MEDOTECH and SHIRAKAWA NITTO KOHKI, came together and became one at the new plant. Along the timeline are actual products, "legends" in their own eras, representing each period. For example, visitors can follow the evolution of ATRA ACE®, one of the company's flagship drilling tools, from a large-scale machine to a compact model, and onward to a battery-powered cordless type, an experience that also invites visitors to appreciate the product's own history.

To determine what the timeline would include and what would be displayed, Ohashi and Nishikiori traveled from site to site, holding repeated discussions with the TOHOKU NITTO KOHKI team. Tracking down period photographs and products, in particular, proved to be a demanding process. "We had to visit the sites that were spread across Yamagata, Shirakawa, and Tokyo multiple times, then select what to include from a huge volume of materials and products, and pull it all together into a single timeline," says Ohashi. Nishikiori looks back with a smile, "It felt like a treasure hunt, like excavating the pieces of a story."

In the "Touch" zone, the team pursued not only clarity and enjoyment, but safety as well.

"We want to invite nearby elementary and junior high school students to the factory and have them actually touch the products and experience them. So we asked for safety first and foremost, and above all, that no one gets hurt," says Kuwabara.

For example, in the hands-on display for JET CHISEL®, a tool that uses compressed air to strip paint, the design was carefully engineered, lowering the tool's power to reduce vibration, using an acrylic case to prevent contact with the needle while in motion, and ensuring the operation could be stopped instantly if needed. "It was challenging to raise the safety level while still tuning it so visitors could truly experience the product's characteristics," says Ohashi.

Another flagship product, the Delvo® electric screwdriver, is used in assembling electronics and automobiles, and is known for features such as stopping precisely when tightening is complete, with minimal impact when it comes to a halt. To let visitors feel those strengths for themselves, the team installed six screws per station and created an exhibit where visitors can hold a "screw-tightening race" between the Delvo and a manual screwdriver. Delvo is suspended using a BALANCE ACE®, the same tool balancer actually used on the plant floor, but its positioning and layout were adjusted with safety in mind to prevent it from striking visitors on the head. The screw-tightening race was originally conceived with children in mind, but in practice, adult visitors enjoy it just as much.

The "See" zone, which serves as a plant tour route, offers a glass-walled view across the equipment, but because the plant is so spacious, it can be difficult to see individual products or the details of employees' hands-on work. To bridge that distance, the team produced panels and videos explaining technologies and fine-grained equipment details, and installed them along the corridor.

This was also a point of strong commitment from TOHOKU NITTO KOHKI. "We asked for explanations that students could understand, and for them to be easy to follow. We want people to learn about the technologies that we are proud of. At the same time, there are processes that fall under non-disclosable know-how, so while omitting those steps as requested, NOMURA MEDIAS still organized the exhibits so the technology comes through clearly," says Kuwabara. He adds that careful attention was also paid to the wording throughout the exhibits. "We debated each term, even down to whether a phrase should be 'polishing' or 'grinding,' and examined the content word by word."

Exhibition design that pursues

clarity and safety while communicating

the appeal of manufacturing

As "teammates" beyond company lines, sharing the same perspective,

working through challenges, and aiming higher together

Looking back on the project as a whole, Kuwabara says, "Above all, we felt the enthusiasm and passion from everyone at NOMURA MEDIAS. They noticed even the smallest details and brought us so many ideas and proposals." They sat down face to face for day-long, even two-day discussions, and also held online meetings almost every week. Often, the conversation could not be wrapped up within the scheduled time, leading to extended sessions or additional meetings set for the next day, with the same intense discussions continuing again and again. "I believe we were able to take on the project as one team, working through challenges from the same perspective and aiming higher together," adds Nishikiori.

Refined relentlessly right up until the eve of the completion ceremony, the showroom was finally brought to life. That commitment reached visitors as well. "Hearing people say it was wonderful made me truly happy," says Kuwabara.

The "Touch" zone has been especially well received, not only for the screw-tightening race, but also for the door closer exhibit, which has drawn an even bigger response than expected.

"By carefully revealing the internal structure of technologies that are not flashy, yet work quietly in familiar places, visitors react with real excitement, saying 'So this is NITTO KOHKI's technology.' Many people have even told us they now check the door whenever they come across one," says Kuwabara.

Along the corridor in the "See" zone, panels were created and installed to explain the factory's automation systems. The panels communicate that automation is not only about efficiency and productivity, but also "automating hot and hazardous work with robots to ensure employee safety." Visitors noted that they could sense that this is a company that values its employees. "I feel that the NITTO KOHKI Group's management principles of 'contributing to society' and 'employee well-being' are truly embodied through these exhibits," says Kuwabara.

Looking ahead, the plant will continue improving efficiency under the concept of "people for 8 hours, machines for 24," aiming to become an automated plant that does not place undue burden on employees. "We want to create products here that can reach the world. We will keep raising production efficiency so we can keep pace with the product development and design work underway at NITTO KOHKI headquarters, and we want to grow TOHOKU NITTO KOHKI as the NITTO KOHKI Group's mother plant," says Kuwabara. He adds that inquiries and visits from overseas are already increasing, and continues, "We also want to invite local children and spark their interest in TOHOKU NITTO KOHKI products through the exhibits. By letting them actually touch these world-class technologies, I hope we can create a positive cycle that leads them to think they might want to work here someday."

President and Representative Director Takashi Chiba also reflects, "We kept discussing things until the very end, until every member of the team was fully satisfied, and that is how this outstanding showroom was completed." He continues, "With this showroom, visitors can learn what kind of environment TOHOKU NITTO KOHKI works in, and how we manufacture, and they can directly feel the fun and excellence of making things. Through the 'Learn,' 'Touch,' and 'See' experience, we aim to be a company rooted in the local community, while also sharing the NITTO KOHKI Group's technological capabilities with the world, from Ozaso."

The technologies cultivated across two bases, Yamagata and Shirakawa, have now merged in Ozaso, as TOHOKU NITTO KOHKI takes its next step forward. This showroom, created to communicate employees' commitment to manufacturing, becomes a new place for connection in the community, linking history and the future.

-

CREDIT

-

- NOMURA MEDIAS Co., Ltd.

- Account Producer: Takashi Sakamoto, Shunichiro Kohama,Akio Kitagawa

- Planner: Taiji Ishii, Natsumi Nishikiori

- Designer: Minami Ohashi

- Technical Director: Satoshi Iwama

- Product Director: Yuta Kumazawa, Harumasa Miyazaki,Satoshi Inaba

- Project Development: Wataru Takada, Ayano Nagashima

- <CLIENT>

-

TOHOKU NITTO KOHKI Co., Ltd.

NITTO KOHKI Co., Ltd.

Other works

11 Solutions from NOMURA MEDIAS

-

Planning

After understanding our clients’ ideas and analyzing the issues they face, we put forward wide-ranging ideas from concept creation through to detailed plans and content proposals.

-

Design

We create spaces and content that express and embody our clients’ ideas.

-

Layout

We create technical drawings and specifications that give concrete form to how the client's ideas are expressed in the design.

-

Production and

ConstructionWith the right knowledge and judgment, we bring projects to fruition by managing production and construction with commitment to quality, safety, and the environment.

-

Product Development

We research consumer needs, then plan and develop products they are looking for while aligning with the concept and vision behind the space.

-

Sales Promotions and

Promotional itemsWe plan and create sales promotion tools and promotional items that inspire action by consumers.

-

Maintenance

To provide experiences and productions that offer safety and peace of mind, we perform regular maintenance, inspections, repairs, and equipment replacement.

-

Event Organization

To maximize the impact of events, we plan and implement everything from creating spaces to attracting customers and providing customer service support.

-

Store Operation

We create sales spaces rooted in each store’s concept and manage day-to-day operations with its worldview at the center.

-

Content Design

We plan and create original content to support our clients’ businesses.

-

System Devices

We build and install various production system devices to support the implementation of digital content.